19 July, 2018 | Dallas, TX- Dallas, TX- As reported in an article, https://3dprint.com/219843/adaptive-3d-ceo-chemistry/

April 11, 2018 | Dallas, TX

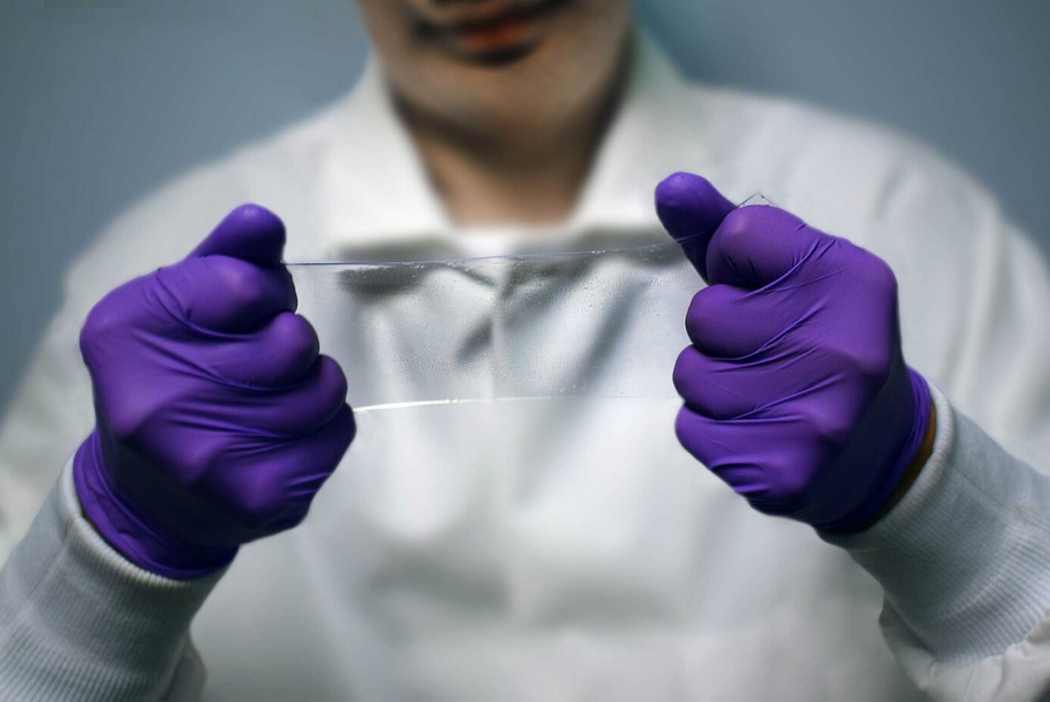

In April of this year, Dallas, Texas company Adaptive3D launched what it said was the highest-strain 3D printable photopolymer in the world. Dr. Walter Voit, CEO of Adaptive3D, played a big role in the development of the material, called ToughRubber, and recently discussed it in more detail. Adaptive3D claims that ToughRubber can stretch to four times, or 450 percent, its original length, absorb deformation and then recover. This is in contrast to many 3D printable materials, which tend to be brittle. These properties could make ToughRubber ideal for numerous applications, such as the aerospace, automotive, medical and footwear industries.

A lot of careful science went into the development of the material, said Dr. Voit.

“There is this critical space between chemists and materials scientists,” he said. “Chemists are dealing with how reactions happen at the atomic scale and material scientists are building parts from the top down. And they kind of meet in this realm—the nano world—and it’s really difficult for computers, still today, to model that world.”

In the lab, Dr. Voit and his team study the physics of polymers and the properties of mixing compounds and ratios. In addition to the development of ToughRubber, the team has made several fascinating discoveries through their work. For example, they worked with a sulfur-hydrogen group called thiols, which have a rapid reaction with other components. The team discovered how to change this reaction to the thiol groups using the right combination of monomers, oligomers, dyes, inhibitors, initiators, sensitizers, and fillers, resulting in materials that can produce strong and durable 3D printed products.

In the lab, Dr. Voit and his team study the physics of polymers and the properties of mixing compounds and ratios. In addition to the development of ToughRubber, the team has made several fascinating discoveries through their work. For example, they worked with a sulfur-hydrogen group called thiols, which have a rapid reaction with other components. The team discovered how to change this reaction to the thiol groups using the right combination of monomers, oligomers, dyes, inhibitors, initiators, sensitizers, and fillers, resulting in materials that can produce strong and durable 3D printed products.

ToughRubber is another addition to the growing market of functional 3D printable materials, meant not just for prototyping or visual appeal but for actual use in final products. Next, Adaptive3D is looking towards using 3D printing to develop sneakers.

“So what we’re trying to do is lighten that midsole portion to more effectively translate stresses and strains from your leg, knee, foot to ground—to have a lighter-weight shoe that’s more comfortable; that gives you more energy back when you’re running,” said Dr. Voit. “It uses less material, it’s greener, it’s more sustainable, and it’s made with superior plastics and then rubbers.”

Dr. Voit is also a tenured professor at the University of Texas, Dallas, and took a sabbatical to work with Adaptive3D on the development of 3D printing materials. The research that went into ToughRubber began at the university.

“What’s been exciting is to see this whole team of great scientists, researchers, and chemists—a lot of whom are former students from UT Dallas—getting to be in the lab making these discoveries daily and weekly,” he said. “Success really is luck—you’ve got to be in the right place at the right time and get lucky. To the credit of the administration here, they’ve created that right place and right time and so now it’s up to really talented teams to get lucky. That’s happening with greater and greater frequency and I’m very excited about what we can do for Dallas, for Texas, and for the country.”

Thiols have been an exciting area of study since the seventies. Indeed previous generations of scientists have all noticed the interesting characteristics of thiol materials. What Dr. Voit is so far mum about is if he has solved the major issues with these kinds of chemicals. Traditionally the instability of thiols has meant that they could, once they’ve been mixed, not last long in a stable state. This coupled with the strong sulfur stench has made these thiol materials far from viable traditionally. It seems that Dr. Voit has, as others have before him, found the interesting characteristics that drive people to thiols. He will have to solve the stench and the processing problems for there to be any true progress here though.